wiring tests

Even on an internally regulated alternator there can be faults in the wiring and circuits leading to the alternator which can make it not charge. Test the wiring before you replace the alternator! Some vehicles have a fuse which can blow and keep the alternator from charging. Others won't charge if the alternator warning light bulb is burned out! On older Chrysler products (80's), and some newer vehicles of other manufacturers, (2000+) the alternator is controlled by the computer. The wire from the large terminal (usually labelled "B+") to the battery can have high resistance, usually caused by a bad connection at either the starter or battery "+" terminal. While the car is running, check the voltage both at the back of the alternator (B+) and the positive battery terminal. They should be within a few tenths of a volt of each other. If not, there may be excessive resistance in the circuit. Many vehicles have a fusible link or a large fuse to protect the alternator. These can be burned up by a short or improper use of jumper cables. If there is no power at the alternator B+ (large output terminal) then a bad fusible link or maxi-fuse is probably the problem.

GENERAL WIRING DIAGNOSTIC TEST PROCEDURES

WARNING!!! THE FOLLOWING DIAGNOSTIC TEST PROCEDURES ARE GENERAL FOR INTERNALLY REGULATED ALTERNATORS.. THEY DON'T APPLY TO EVERY ALTERNATOR EVER MADE. THESE TESTS ARE NOT MEANT TO REPLACE DIAGNOSTIC TEST PROCEDURES FROM A MANUAL OR WIRING DIAGRAM DEALING WITH YOUR SPECIFIC CAR OR ALTERNATOR!!!

(Message to legal types: Shoo! Shoo!)

On an internally regulated alternator there are generally 3 terminals. (not including ground: most alternators ground through their cases where they bolt to the engine). The large terminal goes to the battery: it's the 14.2 volt output terminal.

Another terminal "turns the alternator on", or provides a sensing voltage for the regulator: it generally gets 12 volts from the "ignition switch on" circuit. The third terminal usually goes to the "alt" or "bat" warning light.

Do these tests before you condemn the alternator and do an unnecessary repair!

On MOST cars, with the ignition switch in the run position, (ENGINE OFF!!! JUST ALL THE DASH LIGHTS LIT UP!!!), good alternator wiring should test like this:

The big terminal should have battery voltage (12 volts or so)

One of the small terminals should also have battery voltage (maybe a little less)

The other small terminal should have some voltage (whatever flows through the bulb)

Basically MOST internally regulated alternators should have some positive voltage going to all their terminals with the ignition on. If an internally regulated alternator has those voltages and still doesn't charge then you have a bad alternator.

EXTERNAL VOLTAGE REGULATORS AND OLDER VEHICLES

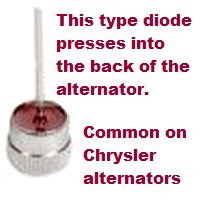

All alternators have a voltage regulator circuit which keeps the voltage at the ideal 13.8 to 14.2 volts needed to run the car and charge the battery. Most newer vehicles have a voltage regulator which is part of the alternator, but older vehicles have the regulator as a separate part. Some Chrysler products used the vehicle computer to operate the alternator. Other manufacturers have recently resurrected this practice of making the voltage regulator part of the computer.

On most other older vehicles the regulator was mounted on the inner fender or the firewall. Testing is different for different vehicles and I can't go into all the different tests here, but any good repair manual will have test procedures for making sure the regulator is OK. So if you have a vehicle with a charging problem, and it has an external regulator, make sure to test the regulator before you replace the alternator!

REASON FOR COMPUTER CONTROLLED ALTERNATORS

Here's why automakers make cars with the voltage regulator as part of the vehicle computer: With an internally regulated alternator the voltage may be lower under the dash than under the hood. A lot of computer and electronic stuff lives under the dash, and is very picky about correct voltage. When the vehcle computer controls the voltage, the voltage is very stable under the dash, making the computer and electronic stuff happy.

Disadvantages of Computer Controlled and External regulated Alternators

Computer controlled alternators have their problems. First it's harder to diagnose a bad alternator. If you wire up an internally regulated alternator correctly it WILL work, and if you replace it you know you have fixed your problem testing is fairly easy. With an externally regulated alternator, the alternator is no longer an "integrated charging package", where: "everything charging system" is part of the alternator.

Testing is not that hard though. On the old external regulator equipped cars the regulators are fairly inexpensive. Not so with computer controlled alternators! If the regulator goes bad you have to replace the computer. It IS possible to put an external voltage regulator on a vehicle with a bad computer controlled regulator, although this MAY cause some electronic issues. Here's a guy replacing a Jeep Grand Cherokee